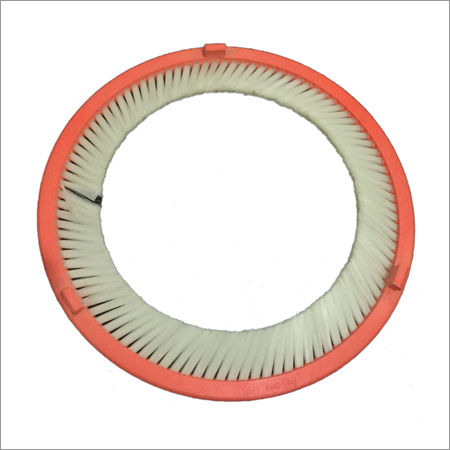

Weft Feeder Disc

Weft Feeder Disc Specification

- Thermal Conductivity

- Moderate

- Noise Level

- Low

- Automation Grade

- Semi-Automatic/Automatic

- Part Type

- Spare Part

- Diameter

- 80-150 mm (Customizable)

- NO. Of Hole

- 6-8 (As per model)

- Mounting Type

- Insert Type

- Hardness

- 52-56 HRC

- Features

- Durable, Wear Resistant, Precision Engineered

- Surface Finish

- Polished / Smooth Finish

- Size

- Standard/Custom

- Capacity

- High-Performance

- Tensile Strength

- High Tensile Strength

- Product Type

- Weft Feeder Disc

- Material

- High-grade Alloy or Stainless Steel

- Textile Machine Type

- Weaving Looms, Automatic Looms

- Spare/Component Type

- Textile Machine Spare

- Usage

- Weft Insertion in Weaving Process

- Speed

- Up to 1000 rpm

- Dimension (L*W*H)

- As per requirement

- Weight

- 150-300 g (approx.)

Weft Feeder Disc Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 10000 Pieces Per Day

- Delivery Time

- 1 Days

About Weft Feeder Disc

Features:

- Elevated durability

- Easy to fit

- Dimensionally accurate

- Perfect finish

High-Precision and Durability for Enhanced Loom Performance

Manufactured from premium alloy or stainless steel, our Weft Feeder Disc delivers superior wear resistance and high tensile strength. This ensures reliable operation even in demanding textile manufacturing environments. Its smooth, polished surface minimizes abrasion and fiber snagging, contributing to consistent fabric quality and extended service life.

Universal Compatibility and Easy Installation

Designed to suit most automatic and semi-automatic weft feeders and weaving looms, the disc can be supplied in standard or custom diameters (80150 mm). The insert-type mounting system simplifies installation, while the ready-to-fit delivery condition allows for immediate integration into production lines, reducing downtime.

FAQs of Weft Feeder Disc:

Q: How does the Weft Feeder Disc contribute to the weaving process?

A: The disc facilitates smooth and precise insertion of weft yarn during fabric weaving, ensuring continuous production with minimal interruptions. Its high-performance design supports high-speed operations, resulting in improved efficiency and fabric quality.Q: What are the maintenance requirements for this Weft Feeder Disc?

A: This component is engineered for low maintenance due to its corrosion-resistant and heat-resistant materials. Regular inspection and occasional cleaning are sufficient for optimal longevity and performance.Q: When should I consider replacing my current weft feeder disc with this model?

A: Consider replacement if you notice signs of excessive wear, increased noise, reduced precision in weft insertion, or frequent loom stoppages. Upgrading to this high-precision, durable disc can help restore optimal performance.Q: Where can this Weft Feeder Disc be used in the textile industry?

A: This disc is compatible with a broad range of weaving looms, including automatic and semi-automatic systems, making it suitable for fabric manufacturers, textile mills, and anyone involved in woven textile production.Q: What is the process for customizing the disc to my requirements?

A: Customization is available for diameter (80150 mm), number of holes, and dimensions. Provide your machines specifications when ordering to ensure a precise fit for your textile equipment needs.Q: What are the key benefits of using this Weft Feeder Disc over conventional options?

A: Benefits include excellent durability, high-temperature and corrosion resistance, low noise operation, and minimal maintenance. Its robust construction and precision engineering also enhance fabric weave quality and machine uptime.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Weft Feeder Disc Category

Weft Feeder Brush

Price 100

Minimum Order Quantity : 10 Pairs

Textile Machine Type : Other, Automatic Looms, Weaving Machines

Usage : Other, Guiding and feeding weft yarn

Weight : Lightweight (approx. 2050 grams)

Dimension (L*W*H) : Custom as per machine compatibility

Somet Super Excel Tape Guide and Slay Guide

Textile Machine Type : Somet weaving machines, Other

Usage : Other, Guides tape and slay during weaving operations

Weight : Lightweight construction

Dimension (L*W*H) : Standard dimensions as per Somet Super Excel model tape guide and slay guide specifications

P1001Tape guide

Textile Machine Type : Other, Warping Machine

Usage : Other, Guides the tape in textile machinery

Weight : 150g

Dimension (L*W*H) : Length: 500mm Width: 20mm Height: 10mm

Weft Feeder for somet vamtex and Weaving Loom

Textile Machine Type : Other, Weaving Loom

Usage : Other, Used in textile weaving to feed weft yarn

Weight : Approximately 5 kg

Dimension (L*W*H) : Standard dimensions for Weft Feeder

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry