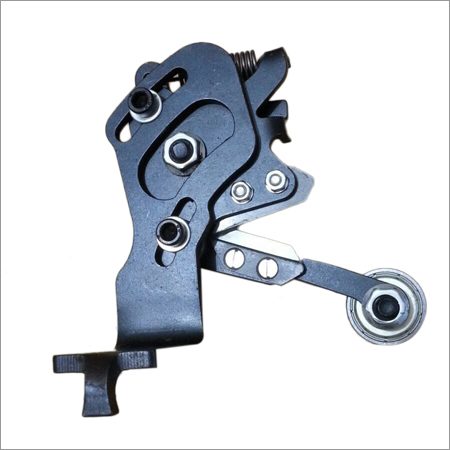

Vamatex P1001 Centre Cutter

Vamatex P1001 Centre Cutter Specification

- Part Type

- Centre Cutter (Shear Knife)

- Mounting Type

- Screw Mount

- NO. Of Hole

- 2

- Size

- Standard/Compatible with P1001 model

- Hardness

- 58-62 HRC

- Noise Level

- Low

- Tensile Strength

- High

- Capacity

- Supports continuous loom operation

- Diameter

- Approx. 40 mm

- Features

- Precision edge, rust-resistant, long service life

- Thermal Conductivity

- Good

- Automation Grade

- Manual / Compatible with automatic looms

- Surface Finish

- Polished

- Product Type

- Centre Cutter

- Material

- High-Speed Steel (HSS)

- Textile Machine Type

- Vamatex P1001 Rapier Loom

- Spare/Component Type

- Loom Spare Part

- Usage

- Centre fabric cutting on rapier looms

- Speed

- Up to 700 rpm

- Dimension (L*W*H)

- 80 mm x 25 mm x 8 mm

- Weight

- Approx. 100 grams

- Precision

- High precision for clean fabric cut

- Sharpening Requirement

- Periodic sharpening for optimal performance

- Edge Type

- Double-sided sharp blade

- Compatibility

- Vamatex P1001 and similar rapier looms

- Blade Length

- 60 mm

- Packaging

- Individually packed in protective casing

- OEM/Aftermarket

- Aftermarket quality replacement part

- Replaceability

- Easy to install and replace

- Operator Safety

- Designed with finger safety guard

- Corrosion Resistance

- Yes, with special surface treatment

Vamatex P1001 Centre Cutter Trade Information

- Minimum Order Quantity

- 10 Pieces

- Supply Ability

- 10000 Pieces Per Day

- Delivery Time

- 1 Days

About Vamatex P1001 Centre Cutter

Features:

- Simple to fit

- Durable

- Aid to perform smooth operation

- Less maintenance

Exceptional Precision and Safety

The Vamatex P1001 Centre Cutter is engineered for high-precision fabric cutting, ensuring minimal fabric distortion and consistently clean edges. The integrated finger safety guard enhances operational safety, making it reliable for both manual and automatic loom systems.

Corrosion-Resistant High-Speed Steel

Constructed from durable high-speed steel (HSS), the centre cutter boasts a polished, rust-resistant surface. Special surface treatments extend blade longevity even in humid or challenging textile environments.

Easy Maintenance and Installation

Thanks to the screw mount design and standard sizing, this cutter is straightforward to install or replace. Periodic sharpening maintains optimal performance, while individual protective casing ensures each blade arrives in perfect condition.

FAQs of Vamatex P1001 Centre Cutter:

Q: How do I install the Vamatex P1001 Centre Cutter onto my rapier loom?

A: The centre cutter is designed with a standard size and screw mount for quick installation on Vamatex P1001 and similar rapier looms. Ensure the machine is powered down, remove the old blade by unscrewing the mount, position the new blade, and securely tighten the screws.Q: What benefits does the double-sided sharp blade offer?

A: The double-sided sharp blade provides a longer service life, minimizing the frequency of replacements and delivering consistently clean, accurate cuts for high-quality fabric edges during continuous loom operation.Q: When should I consider sharpening the cutter blade?

A: Periodic sharpening is necessary for optimal performance. Check the blade condition during routine loom maintenance and sharpen the edge as soon as you notice decreased cutting quality or increased resistance during cuts.Q: Where should the centre cutter be positioned for effective use?

A: The centre cutter should be mounted in the designated centre cutting position of the Vamatex P1001 or compatible rapier loom, ensuring the blade aligns precisely with the fabric path for accurate and clean cuts.Q: What is the typical process for replacing the centre cutter?

A: Replacement involves stopping the loom, unscrewing and removing the worn blade, aligning the new centre cutter with the mounting holes, and securing it with the screws. Always confirm the blade guard is in place for operator safety.Q: How does the corrosion resistance benefit loom operations?

A: The specialized surface treatment prevents rust and corrosion, especially in humid environments, thereby extending the cutters operational life and reducing the frequency and cost of replacements.Q: Is this centre cutter compatible with automatic looms as well as manual ones?

A: Yes, the Vamatex P1001 Centre Cutter is suitable for both manual and automatic loom systems, supporting seamless, high-speed fabric cutting in diverse textile manufacturing settings.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

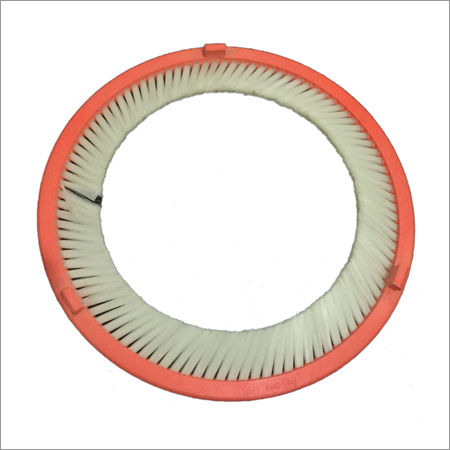

More Products in Weft Feeder Disc Category

Weft Feeder Brush

Price 100

Minimum Order Quantity : 10 Pairs

Textile Machine Type : Other, Automatic Looms, Weaving Machines

Speed : Supports highspeed operation

Weight : Lightweight (approx. 2050 grams)

Material : Other, Nylon/Polyester bristles with metal/plastic core

Weft Feeder Disc

Price 100 INR

Minimum Order Quantity : 1 Piece

Textile Machine Type : Other, Weaving Looms, Automatic Looms

Speed : Up to 1000 rpm

Weight : 150300 g (approx.)

Material : Other, Highgrade Alloy or Stainless Steel

Weft Feeder for somet vamtex and Weaving Loom

Textile Machine Type : Other, Weaving Loom

Speed : Adjustable Speed (Compatible with Somet Vamtex Loom)

Weight : Approximately 5 kg

Material : Other, Metal and Plastic Components

Somet Super Excel Tape Guide and Slay Guide

Textile Machine Type : Somet weaving machines, Other

Speed : Compatible with highspeed textile machines

Weight : Lightweight construction

Material : Aluminum

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry