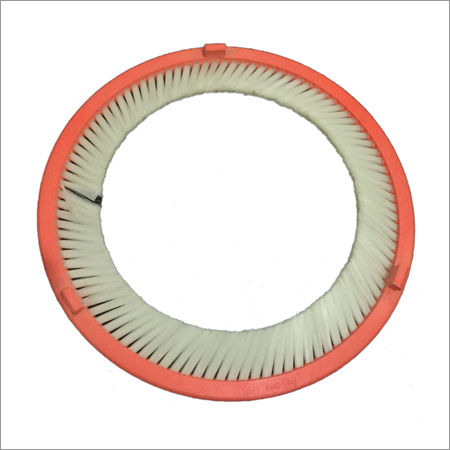

Weft Feeder Brush

Weft Feeder Brush Specification

- Capacity

- High durability for continuous operation

- Thermal Conductivity

- Low

- Hardness

- Medium to high (dependent on bristle type)

- Size

- Standard or as per requirement

- Features

- Anti-static, abrasion-resistant, long life

- NO. Of Hole

- Single/Multiple as per design

- Tensile Strength

- High

- Part Type

- Spare/Replacement part

- Surface Finish

- Smooth, non-corrosive

- Mounting Type

- Snap-fit/Insert type

- Noise Level

- Low

- Diameter

- Approx. 2-5 cm (customizable)

- Automation Grade

- Manual/Semi-Automatic

- Product Type

- Weft Feeder Brush

- Material

- Nylon/Polyester bristles with metal/plastic core

- Textile Machine Type

- Automatic Looms, Weaving Machines

- Spare/Component Type

- Weft Feeder Accessory

- Usage

- Guiding and feeding weft yarn

- Speed

- Supports high-speed operation

- Dimension (L*W*H)

- Custom as per machine compatibility

- Weight

- Lightweight (approx. 20-50 grams)

Weft Feeder Brush Trade Information

- Minimum Order Quantity

- 10 Pairs

- Supply Ability

- 10000 Pairs Per Day

- Delivery Time

- 1 Days

About Weft Feeder Brush

Features:

- Dimensionally accurate

- Seamless finish

- Flawless design

- Excellent strength

Precision Engineered for Weaving Efficiency

This weft feeder brush is meticulously crafted for optimal yarn guidance in weaving machines. Its medium hardness bristles and abrasion resistance maintain yarn integrity while supporting high-speed looms. The smooth, non-corrosive finish and anti-static features minimize wear, ensuring consistent fabric quality and minimal downtime during operation.

Versatile Compatibility and Easy Replacement

Suitable for several major loom brands including Picanol and Tsudakoma, the brush accommodates multiple machine dimensions and configurations. Its tool-free, snap-fit/insert mounting system allows quick replacement during maintenance, keeping production uninterrupted. Custom sizing and color options are available upon request, catering to various textile operations across India.

FAQs of Weft Feeder Brush:

Q: How is the weft feeder brush installed or replaced in weaving machines?

A: The brush features a snap-fit or insert mounting design, allowing for simple, tool-free installation or replacement. This makes maintenance easy and minimizes machine downtime during part changes.Q: What are the usage benefits of the nylon/polyester bristle brush in the textile industry?

A: Nylon or polyester bristles provide durability, abrasion resistance, and anti-static properties. This ensures smooth, guided weft yarn movement and reduces thread breakage, improving operational efficiency on automatic looms and weaving machines.Q: When should the weft feeder brush be replaced for optimal performance?

A: Its recommended to replace the brush if signs of bristle wear, reduced yarn guidance, or diminished anti-static performance are observed. With proper storage, the brush maintains effectiveness for up to 2 years.Q: Where can I use these brushes, and are they compatible with my loom brand?

A: These brushes are designed for weaving units in the textile industry and are compatible with a variety of major loom brands, including Picanol and Tsudakoma. Custom sizing ensures they fit a wide range of automatic looms and machines.Q: What is the process for customizing the brushs size, color, or hole configuration?

A: Simply specify your requirements regarding color, size, diameter, or number of holes when placing an order. The manufacturer will tailor the brush specification to meet your machine and operational needs.Q: What makes this weft feeder brush suitable for high-speed, continuous textile production?

A: With its high tensile strength, medium to high bristle hardness, and robust core, the brush is engineered for long-term durability and consistent performance, sustaining the demands of continuous, high-speed weaving operations.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Weft Feeder Disc Category

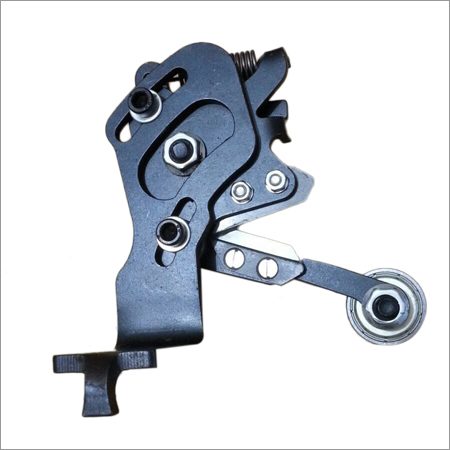

Vamatex P1001 Centre Cutter

Price 500 INR

Minimum Order Quantity : 10 Pieces

Weight : Approx. 100 grams

Spare/Component Type : Other, Loom Spare Part

Product Type : Other, Centre Cutter

Dimension (L*W*H) : 80 mm x 25 mm x 8 mm

Weft Feeder Disc

Price 100 INR

Minimum Order Quantity : 1 Piece

Weight : 150300 g (approx.)

Spare/Component Type : Other, Textile Machine Spare

Product Type : Other, Weft Feeder Disc

Dimension (L*W*H) : As per requirement

Somet Super Excel Tape Guide and Slay Guide

Weight : Lightweight construction

Spare/Component Type : Other, Mechanical spare part

Product Type : Other, Tape Guide and Slay Guide

Dimension (L*W*H) : Standard dimensions as per Somet Super Excel model tape guide and slay guide specifications

Weft Feeder for somet vamtex and Weaving Loom

Weight : Approximately 5 kg

Spare/Component Type : Feeding Unit, Other

Product Type : Weft Feeder, Other

Dimension (L*W*H) : Standard dimensions for Weft Feeder

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry