Call: 08045802323

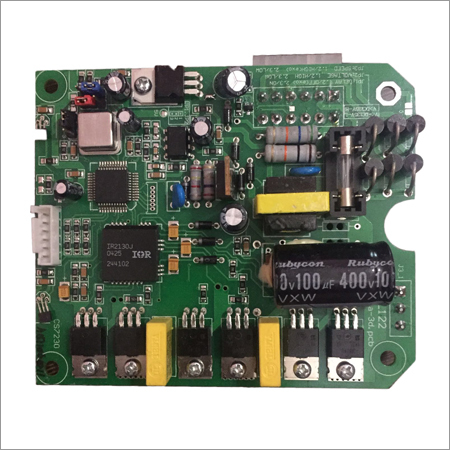

Weft Feeder Card

Price 1900 INR/ Carton

MOQ : 1 Carton

Weft Feeder Card Specification

- Interface

- Screw terminals / pin header

- Thermal Conductivity

- Standard

- IP Rating

- IP20

- Power Source

- External power input

- Display Type

- No display

- Features

- Robust design, easy integration, high reliability

- Usage

- Textile weaving machines

- Response Time

- Instantaneous signal processing

- Input

- Electronic signal for weft feeding

- Operating Temperature

- 0C to 60C

- Power Supply

- Electric

- Components

- Printed circuit board, connectors

- Output

- Controlled yarn feed to loom

- Product Type

- Weft Feeder Card

- Application

- Weaving Machinery

- Rated Voltage

- 24 V

- Supply Voltage

- 24V DC

- Size

- Standard compatible size

- Dimension (L*W*H)

- 90 mm x 65 mm x 13 mm

- Function

- Facilitates smooth feeding of weft yarn for high-speed looms

- Color

- White

- Weight

- Approx. 80 g

- Thickness

- 2.5 mm

- Capacity

- Designed for continuous operation

- Current Rating

- 2A

- Frequency

- 50 Hz

About Weft Feeder Card

Owing to our transparent business practices, we have been betrothed in offering Weft Feeder Card for Textile Machines. Under the supervision of skilled professionals, these Jacquard PCB & Embroidery Machine PCB Board are manufactured using optimum quality raw materials. The offered Textile Machine PCB are installed in industrial machines to control and connect the electronic components. The provided Weft Feeder Card are tested on several parameters to eliminate manufacturing defects. Our clients can avail these Weft Feeder Card from us at cost effective prices.

Features:

Features:

- Accurate dimensions

- Flawless design

- Low maintenance

- Simple installation

Designed for Continuous Operation

This weft feeder card is structured to endure continuous, rigorous use in weaving machinery, ensuring uninterrupted textile production. Its high-grade PCB construction and advanced electronic circuitry offer excellent durability, even in challenging industrial settings. Its compact size and low weight allow for easy installation into new or existing looms without major adjustments.

Universal Compatibility and Easy Integration

The card is built with a standard size compatible with the majority of automatic looms, making integration simple for manufacturers, dealers, and operators. Its screw terminal and pin header interface facilitate efficient installation, while its slot/panel mount design secures it firmly within the machinery.

Advanced Protection and Reliability

Integrated short circuit and overload protections safeguard both the weft feeder card and the loom, fostering long-term reliable operation. The IP20 rating provides additional safety for indoor textile settings, while high humidity tolerance up to 85% RH guarantees stable performance in demanding environments.

FAQs of Weft Feeder Card:

Q: How does the Weft Feeder Card facilitate smooth weft yarn feeding in high-speed looms?

A: The card processes electronic signals instantly and delivers controlled yarn feed with stable voltage and current, ensuring consistent, smooth delivery for fast-moving looms. This minimizes yarn breaks and improves weaving efficiency.Q: What machines and environments is the Weft Feeder Card compatible with?

A: This product is universally compatible with most automatic weaving looms, thanks to its standard size and design. It operates reliably in environments with up to 85% relative humidity and temperatures ranging from 0C to 60C.Q: When should I consider replacing or maintaining the Weft Feeder Card?

A: Though the card is designed for low maintenance and robust, continuous operation, it is advisable to inspect connections and check for potential overload or short circuit events during scheduled loom maintenance to ensure optimal functioning.Q: Where is the ideal mounting position for installing the Weft Feeder Card?

A: The card is suited for either slot or panel mounting within the looms control unit, making it adaptable to a variety of machine configurations prevalent in textile mills and weaving facilities.Q: What is the process for integrating this card into existing textile weaving machinery?

A: Simply connect the feeder card using its screw terminals or pin headers and mount it securely using the designated slot or panel in your loom. Its compact dimensions and universal interface ensure straightforward integration.Q: Which features make this Weft Feeder Card beneficial for textile manufacturers and suppliers?

A: Key benefits include reliable protection (short circuit and overload), fast signal processing, low maintenance requirements, robust design, and high compatibility, all contributing to improved operational efficiency and product longevity.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry